From discharge technology to rotary valve

Silo components of bissinger – the complete system

We deliver all the necessary accessory parts for your new plants or for modification / redevelopment.

Overfill / underfill protection consisting of:

- Filter

- Max. detector

- bissinger pressure relief / vacuum valve

- Regulation in conformity with BGV C12

- No mechanically moved parts

- Simple assembly

- Safe

- Robust

- Pressure monitor

- Slider / squeeze valve

Wear protection

In case of wearing products, the service life of the silo can be increased by means of various measures:

In pipelines

bissinger large wear protection radii

Most durable cast elbow in its class

Minimal pressure loss by large radius

Low-wear transport of abrasive bulk material

Material: Grey cast iron

Nominal width 100

90° diversion

In containers

Increase of the statically required sheet metal thickness

Wear protecting lining of the silo with stainless steel, Hardox, plastic or rubber

Inside coating as corrosion protection or reduction of the material adhesion

Static calculation in conformity with German standard DIN EN 1090 under consideration of environmental conditions, such as earthquakes, wind, snow or bulk material analysis

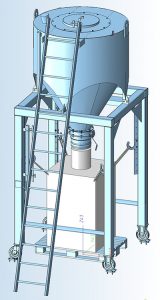

Big-Bag plants

- For manual filling of Big-Bags, for example loading plants, when requested

- With heavy-duty rollers for hand transport

- With mount for forklift transportt

- With filling and emptying control

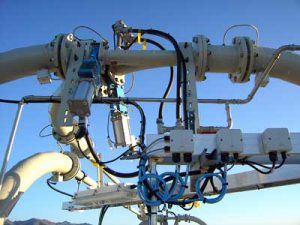

Measurement and safety technology

- Level limit switch: capacitive probes, vibration and rotating paddle sensor, continuous filling level measuring systems, in ultrasound, capacitive or gravimetric execution

- Temperature controller

- Pressure monitor

- Load cell

- Explosion door for explosion relief

Conveyor systems

- Filling pipe and pipe connection galvanized or varnished

- Pneumatic conveyor systems for every individual case: Dense phase or plug conveying plants, blown delivery plants as pressure or suction delivery, for building materials, coal, sewage sludge, ash, plastic, chemical products and food in all sizes

- Designed especially for your demand

Discharge technology

- For fine-powder or coarse-grain, fluidisable or agglomerated bulk material

- Aeration systems in nozzle or cushion version; to be replaced from the outside even

- Air cannons for slow-flowing bulk materials

- Vibrating cones

- Shut-off devices, such as flaps or slides, with manual operation, pneumatically or motor driven

- Forced discharge systems such as screws or rotary valves

- Loading plant for open and closed lorries or rail wagons, ship loader of up to 1000 m³/h, for gravel, sand, dusty, explosive and corrosive products, housing and cupss in normal and stainless steel excution

Inspection facilities

- Steps and railings in normal or stainless steel; execution as required by the customer

- Folding steps with three, four or five steps, with manual control or electro-magnetic drive, for safe access of lorries and rail wagons

- Ladder with bissinger fall protection on roof outlet For transport silos we have developed a special folding ladder system which minimises the transport dimensions. A time-consuming disassembly of the ladder is thus prevented. When setting up the silo the ladder is folded open with a few quick motions and corresponds to the applicable standards and regulations.

- Cross-over bridges between silo roofs with railings, in all requested executions

- more information...

Do you have any questions or do you want to file a request ?