Tailor-made solutions

Systems for sewage sludge

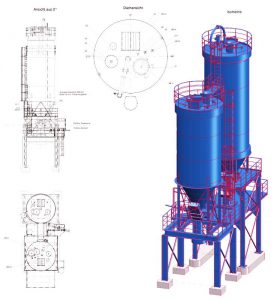

30 plants for dried sewage sludge worldwide in the past 15 years and many plants for wet sludge – bissinger silo plants for sewage sludge enjoy an excellent reputation in the industry. We have acquired well-founded know-how and are very familiar with the properties of a wide variety of sewage sludges.

Our systems are characterized by reliability, durability and an optimal price-performance ratio. We can look back on many years of experience in conveyor and silo systems with all safety devices. Comprehensive advice right from the start – in the offer phase through to long-term operation.

Features of our systems:

- Silos up to 200m³ usable volume factory-welded, in individual cases larger

- construction site welded up to 1000 m³

- Roofs as a conical roof or dished bottom

- generally pressure shock resistant with pressure relief devices

- ATEX compliant

- heated and insulated

- Inerting in an emergency with a bundle of bottles or permanently with nitrogen generators

- Measuring devices for CO and O2

- Dust collectors

- Discharge devices

- Trucks – loading or unloading in or from silos

- Pneumatic conveying, with screws or other mechanical conveyors

- Delivery and assembly worldwide

High quality silo and plant constructions for bulk material in the fields of stones and earths, of the building industry, in power plants, and cycling, chemistry and food branch are produced by bissinger in own development and manufacture..

Silos produced by bissinger are primarily made of quality steel, but can also be made of several special and stainless steel upon request.

Silos in the following executions and specifications can be supplied

- Cone and flat-bottom silos in special sizes up to 500 cum welded in the works, up to over 1,500 cum welded on the building site

- Multi-compartment and partition wall silos

- Heat and insulated when required

- Pressure shockproof

- Designed in keeping with ATEX

- Bunker constructions

- Special constructions (filter drums, chutes, etcetera)

Right from the beginning experienced engineer will assist you with all plants. Thus we make sure that your plant is planned and manufactured individually according to your requests.

Our scope of services includes, among other things

- The procedural interpretation of all plant components

- The preparation of auditable statistics of silos with supporting structure in keeping with the currently applicable regulations

- The performance of bulk material analyses with the result of the static input values in case of unknown products and the design as well as dimensioning of discharge equipment

- Layout plan as well as production drawings created with the latest CAD systems

At the end of your project, there is a convincing and tailor-made individual solution.

- more information...